VENTOR 4150

POTATO DIGGING WITH EVEN MORE COMFORT

At Agritechnica in 2017 the four row self-propelled potato harvester VENTOR 4150 was introduced for the first time.

At Agritechnica in 2017 the four row self-propelled potato harvester VENTOR 4150 was introduced for the first time. For the year 2020 the machine with the Agritechnica innovation award silver medal "machine of the year 2018" many new features.

Driver comfort

Driver's comfort was at the forefront for the further development of the VENTOR 4150. The new comfort-cab with optimized noise insulation makes it very quiet inside. To ensure that the driver remains concentrated and rested at all times, even on long working days, a premium driver's seat is used in the cab. The leather seat with extra high back, the active ventilation, seat heating and air suspension with adjustable shock absorption offer the driver a relaxed workplace. Further features include a big cooling box and radio with hands-free kit as standard.

Everything in sight

The VENTOR 4150 is equipped as standard with the new GRIMME SmartView video system so that the user has an excellent view of the harvesting process and the bunker. Unique functions of the video system are the high-resolution image display with zoom function, live slow motion function,live image transfer on mobile devices via Wi-FI and the freely configurable multi display of the camera images. The SmartView will be launched at the Agritechnica 2019.

Further innovations

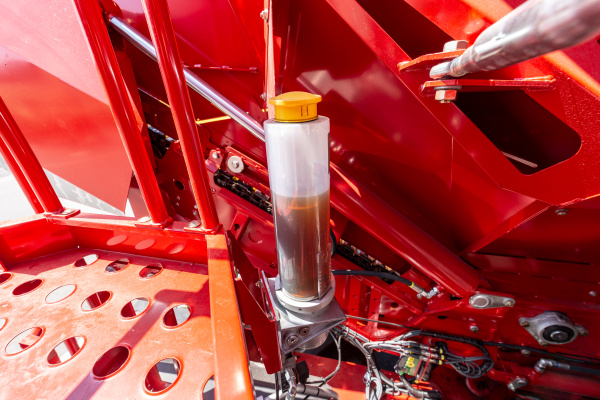

A bunker chain greasing system is standard from 2020 on. The greasing system ensures a longer durability of the bunker chain and increases the comfort for the user as manual greasing becomes void. The powerful Mercedes-Benz engines of the latest generation which fulfil the exhaust emission standard stage V drive the 530 hp strong harvester.

Connection to myGRIMME

As standard, all GRIMME self-propelled harvesters are equipped with a telemetry unit that enables a connection to the customer portal myGRIMME. In myGRIMME machine parameters, the current location and movement history of the machine can be viewed on google maps® at any time. If the user uses a certified agricultural software, farm management information system (FMIS), it is possible to connect this software via the data exchange platform agrirouter with myGRIMME. On request, you can than send machine and GPS data from the machine to the FMIS.

For all self-propelled GRIMME harvesters, there are individual agreed service packages available which include the full service inclusive of wearing parts in the highest stage PROTECT.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates