GRIMME

VENTOR 4150 WITH HAULM TOPPER AND FURTHER FEATURES

For the 2021 season, the four-row self-propelled potato harvester VENTOR 4150 will be equipped with some new practical features.

Equipped for long and tough haulm in potato crops

The VENTOR 4150 can now be optionally equipped with the HT 400 haulm topper, which is especially suitable for extremely high quantities of long, tough potato haulm. In addition to a significant increase in throughput, haulm topping prior to the harvesting process reduces the risk of losses on the deviner web. The potato haulm is widely distributed on the already cleared area by use of a cross conveyor and an integrated haulm spreader. Automatic depth control is monitored via skids on the potato rows and can be conveniently adjusted from the operator terminal in the drivers cab. For road transport, the HT 400 is hydraulically folded over the intake unit.

Picture: The proven haulm topper,HT 400, is especially suitable for long, tough haulm in potato crops.

Reduced soil sticking

For use on heavy soils, highly wear-resistant plastic share blades can be used, which helps reduces soil adhesion and keeps wear to a minimum.

Picture: Share blades made of highly wear-resistant plastic reduce soil buildup in severe, sticky conditions.

Further stone protection on the share blades

In addition to the familiar shear off bolts on the share blades and the share frame, the share arms can now also be protected against overload by a shear off bolt. The required shear force can be varied with three holes for the positioning screws.

Picture: The stone protection prevents damage to the share frame. The shear force can be varied via three holes.

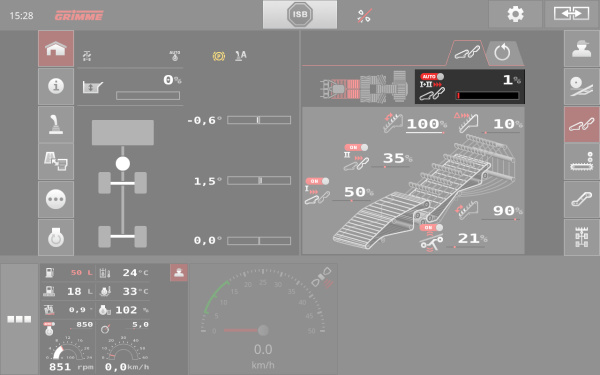

Speedtronic-Web

The optionally available "Speedtronic-Web" automatically adjusts the speeds of the main webs, including the deviner web, in relation to the forward speed of the harvester. The system is particularly characterized by an increase in driver relief and the maximization of crop protection.

Picture: Speedtronic-Web provides automatic speed control of the main webs depending on the driving speed.

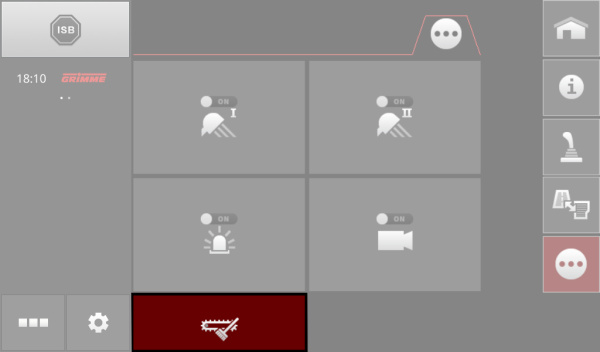

Automatic cleaning of the separators

The feature called "Turbo Clean" facilitates the cleaning operation of certain webs and separators. The drives of the webs and separators are step by step driven with maximum speed so that self-cleaning is achieved. Turbo Clean can be activated manually at the push of a button or automatically at the end of the field.

Picture: With the "Turbo Clean" function, webs and separators are driven at maximum speed for self-cleaning.

Self-propelled harvester on velvet paws

The VENTOR 4150 can be optionally equipped with large-volume tyres "MICHELIN CEREXBIB 2" which have a dimension of VF 900/60 R38. Thanks to MICHELIN UltraFlex technology, these tyres can be run at low inflation pressures, significantly increasing the ground contact area for optimum ground protection and operational safety.

Picture: Enhanced ground protection thanks to the new MICHELIN CEREXBIB 2 tyres.

Fast unloading

The drive of the bunker unloading conveyor was revised in such a way that the unloading time of the 15-ton bunker could be reduced from 90 to just 60 seconds.

Mapping of crop gross weight Digital capturing of harvest masses

For the documentation of harvest masses, the VENTOR 4150 can be equipped with an integrated system for mass mapping. Based on this data, a yield map can be created that visualizes zones of high and low yield. With the help of a Farm Management Information System (FMIS), a map for the site-specific application of i.e. fertilizer, pesticides or seed can be derived from this yield map. All measured values can be stored in ISO-XML format and transmitted using a USB stick or the manufacturer-independent data exchange platform "agrirouter".

Picture: The recorded data is displayed straight on the operator terminal.

Video:

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates