GRIMME MATRIX

WITH SEVERAL INNOVATIONS

At the Agritechnica 2015 Grimme did launch the new mechanical precision seeder, called MATRIX, for sugar and fodder beet, chicory and canola.

At the Agritechnica 2015 Grimme did launch the new mechanical precision seeder, called MATRIX, for sugar and fodder beet, chicory and canola. The machine is available for 12- or 18- rows, either with 45, 48 or 50 cm row width. For 2019, extensive further and new developments have been included.

More comfort for the driver

For greater driver comfort, the clearly arranged 12.1-inch CCI 1200 operator terminal is available as an option, which, among other things, can be used to display several screen contents in parallel.

The adjustment of the pendulum travel of the hydraulic cylinders on the main frame as well as the swivelling of the support wheels for better maintenance of the sowing units is now possible without tools. The spring load of the optional clod clearer for mulch sowing equipment can be adjusted without tools via a lever. The socket for the connection of the optional vacuum cleaner for emptying the residue has been moved to the rear of the machine and is therefore much easier to reach. The spare shear bolts for the lane markers have been placed directly on the lane marker for quick access.

Even more precision

For even higher precision, the production of the separation units has been optimized in cooperation with the supplier. Extensive tests under very different conditions have shown very good to good results even at high speeds.

An offset frame is available for the MATRIX 1200, with which tractors with a track width of 1.5 metres and a row width of 50 cm can work with a track offset so that the sowing units do not run in the tractor track. Teh advantage is a smoother running seeding unit, resulting in more precise depth control and more accurate sowing distances.

In order to ensure optimum compaction at all times, even in uneven conditions of the seed furrow, the range of motion of the V-pressure rollers has been optimised downwards. The spring travel of the discformed furrow closer has also been improved so that uniform back compaction of the seed furrow is ensured by the trailed rollers. The spring pressure is also adjustable.

Additional new and further developments

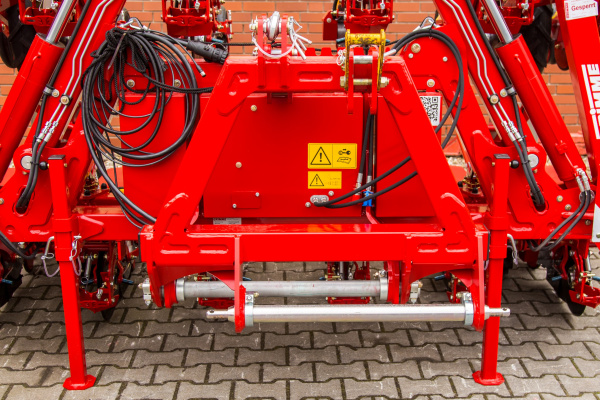

Robust jack stands are available on request to protect the support wheels from deformation during longer parking periods. The new seals on the seed boxes, each holding 10 litres, are now applied precisely by computer control, so that the seal is ideally sealed and wear is significantly reduced. In addition, the snap-in of the seed box lid has been improved. The machine has a hydraulic frame ballast. Until now, one of the drilled holes for the upper link was used for this purpose. Thanks to the revised design, this borehole is now available for the original purpose again. The MAXTRIX is equipped with Section Control (option) and Clever Planting (series) to adjust seeding distances next to the tramlines.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates