GRIMME

THE SPECIALIST FOR VEGETABLE EQUIPMENT

The rapid development of the world's Population increases the demand for powerful and crop-protective technology for harvesting vegetables.

In addition, the shortage of harvest workers poses new challenges for vegetable growers.

The GRIMME Group with its brands SPUDNIK, ASA-LIFT and GRIMME offers the world's most comprehensive range of vegetable technology for onions, carrots, beetroot, chives, parsnips, fennel, celery, leeks, lettuce and other crops such as spinach comprising over 30 product groups.

The Danish manufacturer ASA-LIFT has been active in this field for over 80 years and is regarded as a globally recognised specialist in vegetable harvesting technology with a focus on customised solutions.

This harvester is made entirely of stainless steel to meet the strict guidelines of the lettuce harvest.

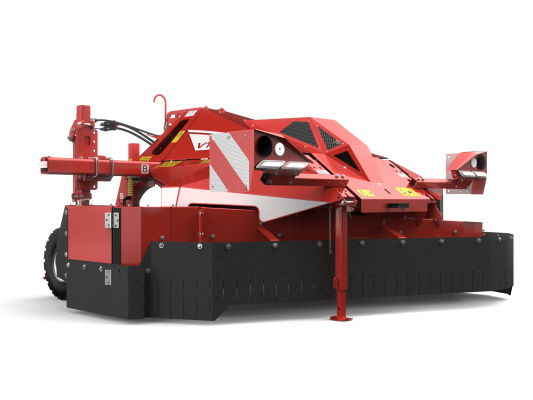

Picture: The US subsidiary SPUDNIK developed a self-propelled spinach harvester built entirely of stainless steel according to customer requirements.

With more than 50 years of experience, GRIMME Landmaschinenfabrik is also at home in vegetable harvesting technology. Machines for harvesting onions or carrots were already being manufactured in the early 1970s.

Today, in addition to a wide range of harvesters, GRIMME Landmaschinenfabrik also develops and produces machinery for soil tillage, harvest preparation and handling equipment.

When storing onions, it is important to take care about the crop and fill the boxes gently.

Harvest storable cabbage by machine

In the past, industrially used cabbage could already be harvested by machine and was immediately marketed or processed into frozen goods. In comparison, the harvesting of storable and thus very sensitive cabbage is currently characterised by manual labour and is becoming increasingly difficult to do, especially due to the lack of harvest workers. With the new MC-1020DF cabbage harvester, ASA-LIFT offers a solution for the mechanised harvesting of storable cabbage. Thanks to the intake unit, which is very close to the ground, and the conveyor belt, which is gentle on the crop, the harvested cabbage enters the box with only a very low drop step. Due to the very low mechanical loads, storage times of up to 6 months can be realised.

The ASA-LIFT MC-1020 DF is a mounted single-row cabbage harvester that gently transports the harvested cabbage into the box.

The multi-talented harvester EVO AllCrop

The proven concept of the EVO 290 potato harvester introduced in 2017, with its soil-protecting three-wheel chassis, large 9 t bunker, wide intake channel and various intake options such as diablo rollers, windrow intake or carrot share, provides the basis for this multi-talent.

The new EVO AllCrop harvester has been specially modified for harvesting carrots, onions, parsnips, beetroot and celeriac in key assemblies. A significant change was made to the separators. Instead of the deviner web and the standard separators, two fine haulm elevators (steep hedgehog webs) are used. These are particularly advantageous for separating impurities and kink-sensitive crops such as carrots or parsnips. Also available is the GRIMME SmartView video system with its 12-inch touch-screen monitor and unique features such as zoom function, live slow motion, live image transmission via WiFi and Visual Protect PRO. This ensures a good overview of all machine functions at all times.

The EVO AllCrop is particularly interesting for growers who grow both carrots and onions, as this machine can be used for both.

The new onion topper of the VT-series

Onion toppers are used for an efficient haulm reduction and pre-harvest treatment before windrowing. With the new VT series, beds can be treated within the track widths of 150 to 225 cm.

The new GRIMME Vegetable Topper is equipped with special upwardly curved blades, which thereby achieve such a high suction capacity that even low-lying, heavy onion tops can be raised and cut off. In combination with an automatic height guidance, this ensures a precise cut at the desired level, so that the onion is not damaged in the process. Only in this way the onion is storable and can be marketed well afterwards. Operation of the VT is convenient and can be done via ISOBUS.

VT 170 - Tractor mounted onion topper for beds up to 180 cm track width.

Innovation

Whether its new machines or digital solutions, you'll find all the latest information here.

Display all updates